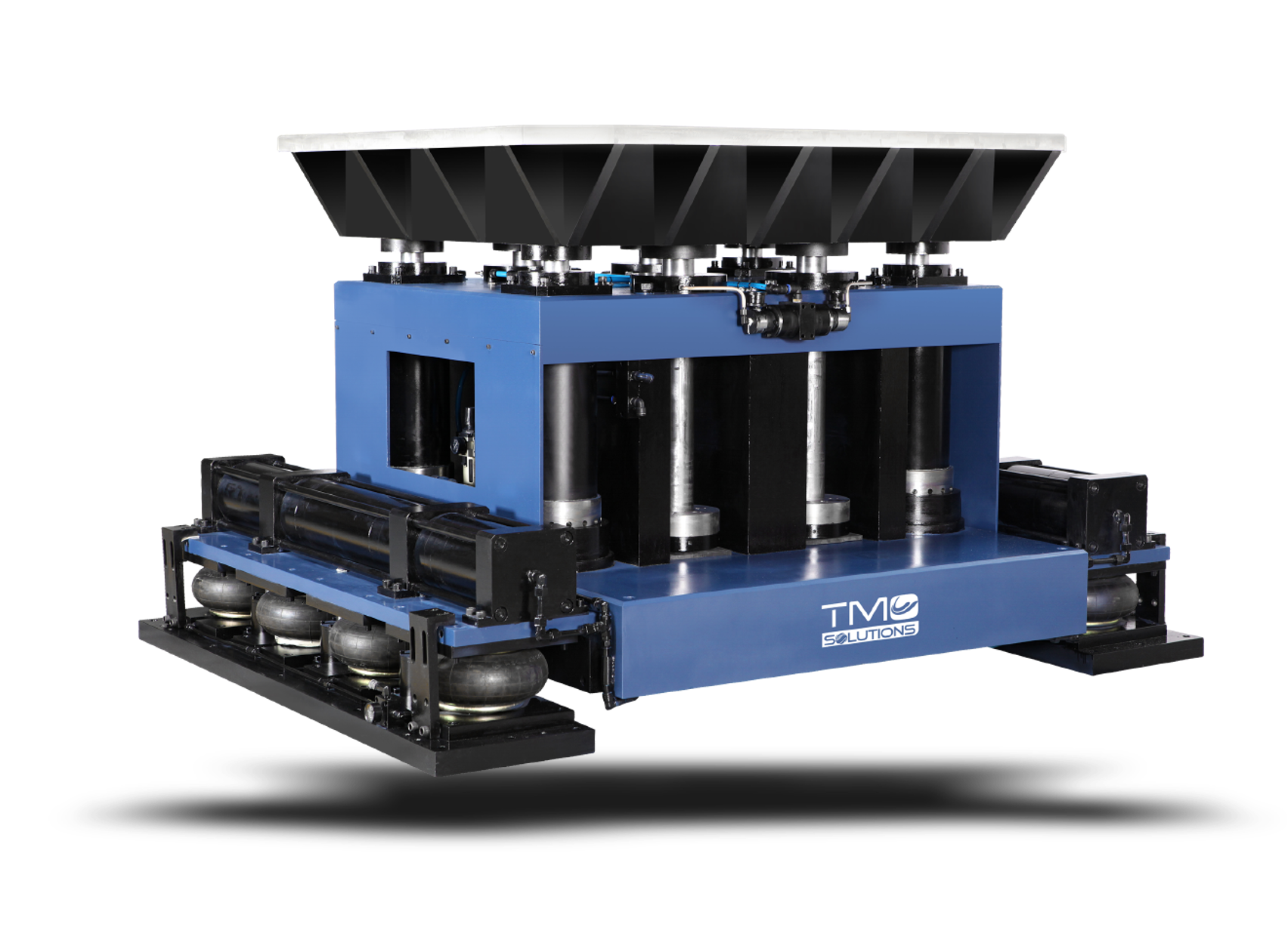

DVAS SERIES

BIDIRECTIONAL PNEUMATIC VERTICAL SHOCK TEST SYSTEM

DVAS Series shock test system can achieve both positive shock and negative shock on one machine. It is typically suitable for specimen which can not be rotated. Combined with HAS Series horizontal shock tester, DVAS can achieve six degrees shock tests.

Based on the VASI series design, TMC researched and developed a modern shock test system which is unique in the world. DVAS series combines positive shock and negative shock in one machine by using special shock machine structure design and special air cylinder design.

DVAS Series bidirectional shock test system is now widely used in the environmental testing, battery testing, etc. The table size is 2000x2000mm or can be customized even larger. With 2 ton or more payload, it can fulfill the customer testing requirements.

FEATURES

The DVAS series pneumatic bidirectional vertical shock test system is uniquely designed and developed for testing large specimens that are difficult to turn over, making it ideal for battery testing. This innovative system effectively conducts vertical upward and downward shock tests within a single test stand, eliminating the need to move the Unit Under Test (UUT). Utilizing pneumatic drive technology, it ensures minimal environmental impact while offering multiple functions in one machine. With built-in pneumatic brake mechanism, the system prioritizes safety and reliability. Providing seamless control and measurement in a single unit, it streamlines operations for efficient testing. Furthermore, the integration of air springs and dampers effectively reduces vibrations, allowing for easy installation without the need for a dedicated foundation.

DOWNLOAD DATASHEET