Boosting Precision with Motion Simulators & Rate Tables

Enhancing Precision with Motion Simulators and Rate Tables in Product Testing

In the fast-evolving industries of aerospace, automotive, and defense, ensuring product precision and reliability is a top priority. Motion simulators and rate tables have become indispensable tools in achieving this goal. By simulating real-world movements and testing rotational accuracy, manufacturers can refine their components to meet stringent quality standards and perform flawlessly in demanding environments.

This article delves into how motion simulators and rate tables enhance precision in product testing, their applications in critical industries, and why investing in these advanced motion systems is essential for modern manufacturers.

What Are Motion Simulators and Rate Tables?

Motion Simulators

Motion simulators are advanced testing systems designed to replicate real-world movements, such as tilts, rotations, and vibrations. These simulators are used to test the dynamic performance of components under controlled conditions. They are widely employed in industries where precision and reliability are critical, such as aerospace, automotive, and military.

Rate Tables

Rate tables, on the other hand, are specialized motion systems used to evaluate the accuracy and stability of sensors, gyroscopes, and other rotational devices. By providing controlled rotational motion, rate tables help manufacturers ensure that these components perform consistently and accurately under various conditions.

Applications of Motion Simulators and Rate Tables in Product Testing

1. Aerospace Industry

Testing Avionics and Navigation Systems: Motion simulators replicate flight dynamics, allowing engineers to test the functionality and reliability of aircraft navigation and control systems.

Gyroscope Calibration: Rate tables are used to evaluate and calibrate gyroscopes, ensuring they can maintain stability during high-speed rotations and extreme altitudes.

Satellite Component Testing: Motion simulators replicate the complex movements of satellites in orbit, enabling precise testing of satellite components.

2. Automotive Industry

ADAS (Advanced Driver Assistance Systems): Motion simulators test the performance of ADAS systems by simulating real-world driving conditions, including turns, tilts, and vibrations.

Sensor Testing: Rate tables are essential for calibrating automotive sensors, such as those used in lane-keeping systems and adaptive cruise control.

Engine Performance: Motion systems simulate vibrations and rotational forces experienced by engines, ensuring durability and efficiency under real-world conditions.

3. Defense and Military Applications

Missile and Weapon Systems: Motion simulators and rate tables evaluate the precision of missile guidance systems and other military-grade equipment.

Rotational Sensor Testing: Rate tables ensure that sensors used in military vehicles and equipment function reliably under extreme conditions.

Benefits of Using Motion Simulators and Rate Tables

1. Enhanced Precision and Reliability

By simulating real-world conditions, these systems provide accurate data on how components will perform in operational environments. This reduces the risk of failure and enhances product reliability.

2. Compliance with Industry Standards

Motion simulators and rate tables enable manufacturers to meet strict industry standards, such as ISO 9001 and MIL-STD-810, which are critical for aerospace, automotive, and defense products.

3. Cost and Time Savings

Early identification of design flaws through motion simulation reduces the need for expensive rework and recalls, saving time and resources during product development.

4. Customizable Testing Parameters

Both motion simulators and rate tables allow for customizable testing, enabling manufacturers to simulate specific scenarios that align with their unique product requirements.

The Science Behind Motion Simulators and Rate Tables

Motion Simulators: Real-World Dynamics in a Lab

Motion simulators use hydraulic or electromechanical systems to replicate real-world dynamics. For example:

A 6-DOF (Degrees of Freedom) motion platform can simulate pitch, yaw, roll, surge, sway, and heave, making it ideal for testing aircraft and automotive components.

Rate Tables: Accuracy at the Core

Rate tables achieve precise rotational control using advanced servo systems. High-end rate tables can offer:

Angular Velocity: From fractions of a degree per second to thousands of degrees per second.

Load Capacity: Suitable for lightweight sensors to heavy-duty gyroscopes.

Why Invest in Motion Simulators and Rate Tables?

Market Growth Insights

The global motion control market, which includes motion simulators and rate tables, is projected to grow at a CAGR of 5.5% from 2021 to 2028. This growth underscores the increasing demand for precision testing systems in industries like aerospace, automotive, and defense.

Staying Ahead of the Competition

With technological advancements driving innovation, manufacturers who invest in cutting-edge motion systems can gain a competitive edge by delivering highly reliable products that meet and exceed customer expectations.

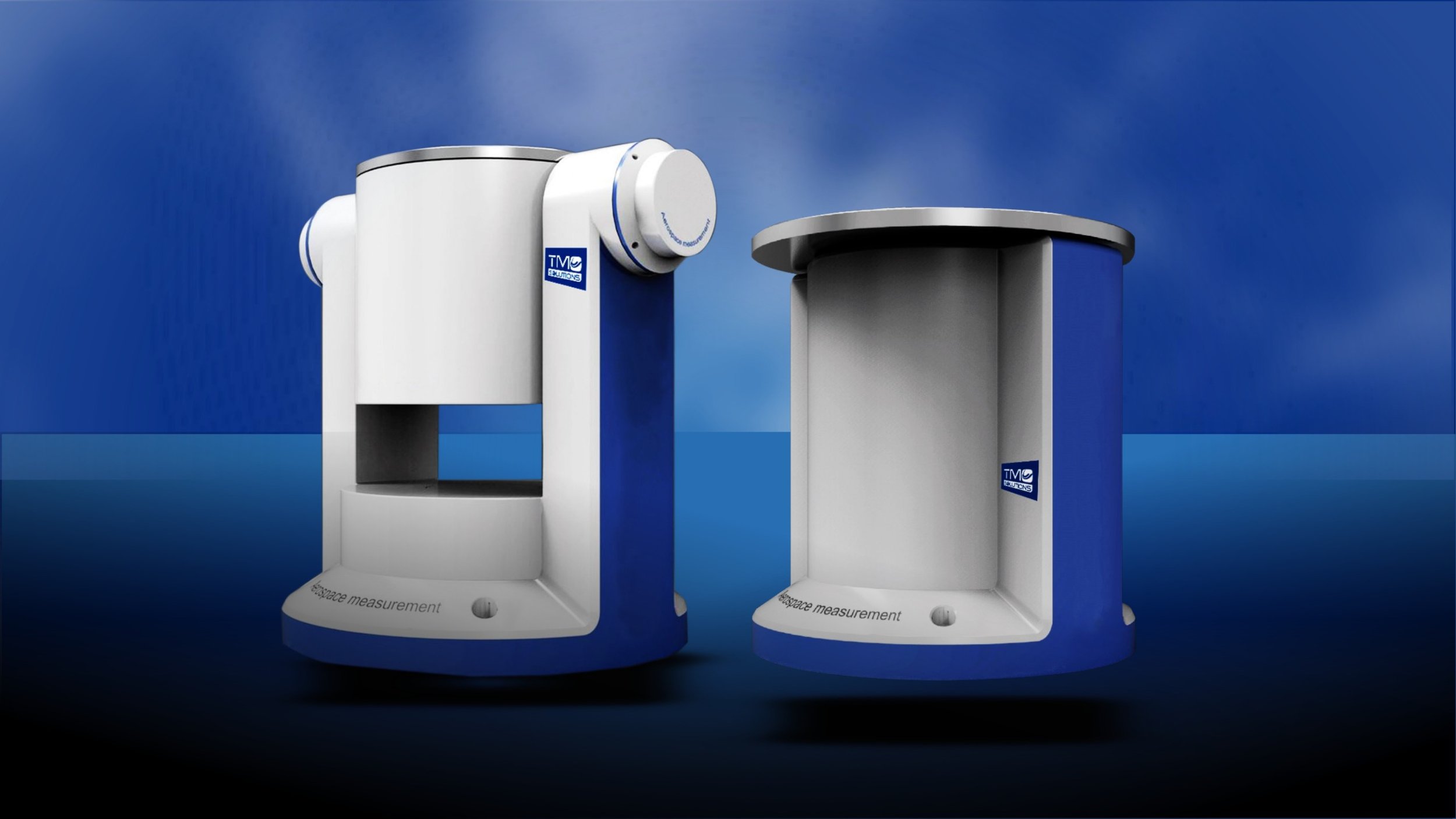

Why Choose TMC Solutions?

At TMC Solutions, we specialize in providing advanced motion systems and rate tables tailored to meet the unique needs of our clients. Our systems are designed to offer:

High precision and repeatability

Customizable testing capabilities

Robust design for long-term reliability

We are committed to helping manufacturers achieve unparalleled product precision and reliability. Whether you need a motion simulator for aerospace testing or a rate table for sensor calibration, our experts are here to guide you.

Contact Us

Interested in enhancing your product testing with motion simulators or rate tables? Contact TMC Solutions today to discuss your requirements and learn how our advanced motion systems can help you achieve your testing goals.