Safety Measures and Best Practices for Operating HSRS1000

Safety is paramount when operating high-performance shock testing equipment like the HSRS1000. This article outlines essential safety measures and operational best practices to ensure smooth, reliable, and risk-free testing.

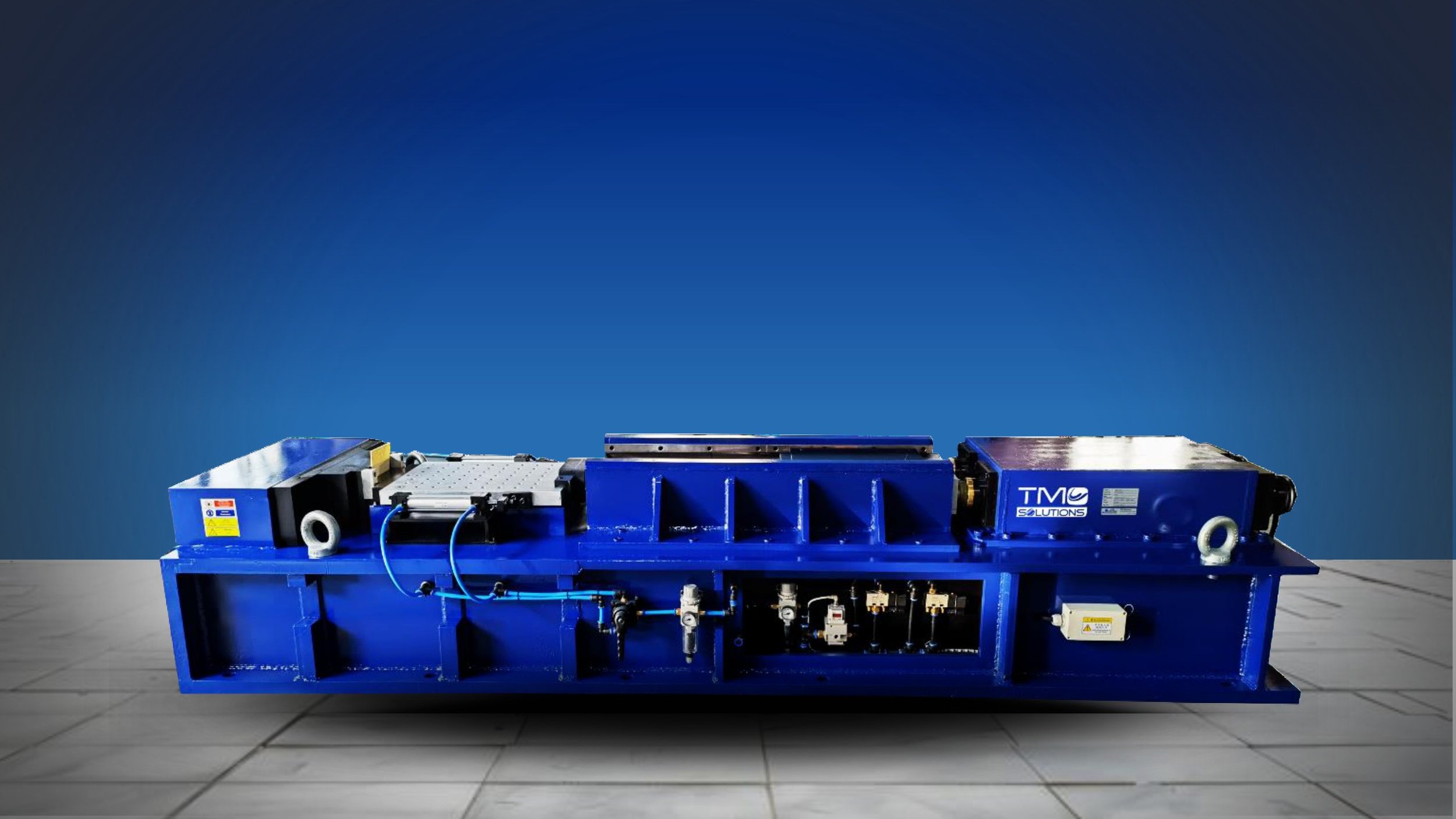

Exploring Features of the HSRS1000 SRS Machine

The HSRS1000 Horizontal Shock Response Spectrum (SRS) machine represents a leap in shock testing technology. Designed for industries such as aerospace, defense, and scientific research, this advanced system offers unmatched precision and flexibility in simulating shock events.

TMC’s Leadership in Large Horizontal Shock Systems

When it comes to shock testing, TMC Solutions stands out as a pioneer in innovation, offering cutting-edge solutions for diverse industries. One of our most remarkable achievements is designing the largest horizontal shock tester in China, setting us apart in precision engineering and testing capabilities.

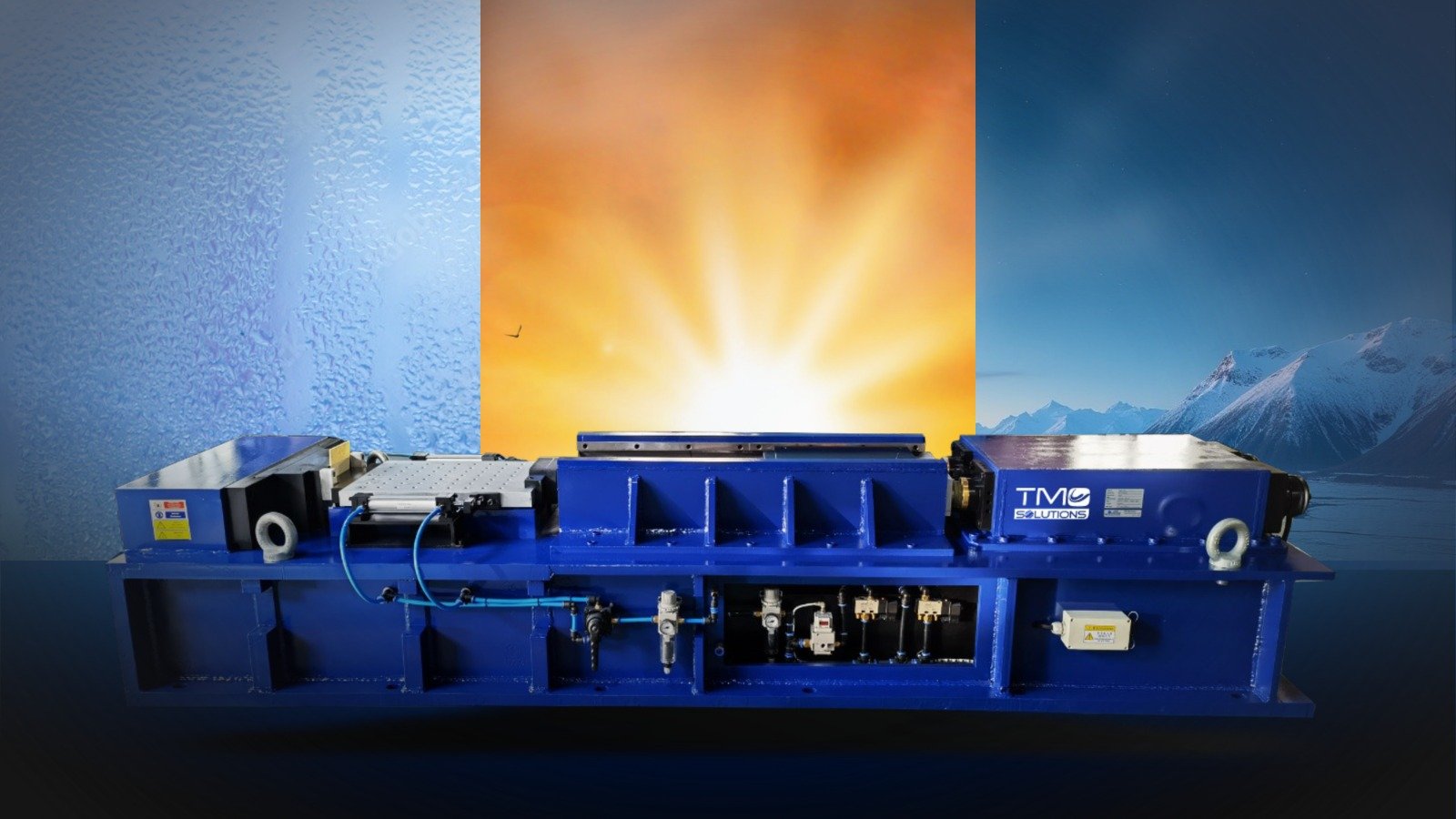

How Environmental Factors Impact Shock Test Results

In the world of product reliability, shock testing is an essential process to evaluate the structural integrity and durability of components under real-world conditions. However, to truly replicate real-world scenarios, manufacturers must account for various environmental factors—such as temperature, humidity, and pressure—that can significantly influence shock test results.

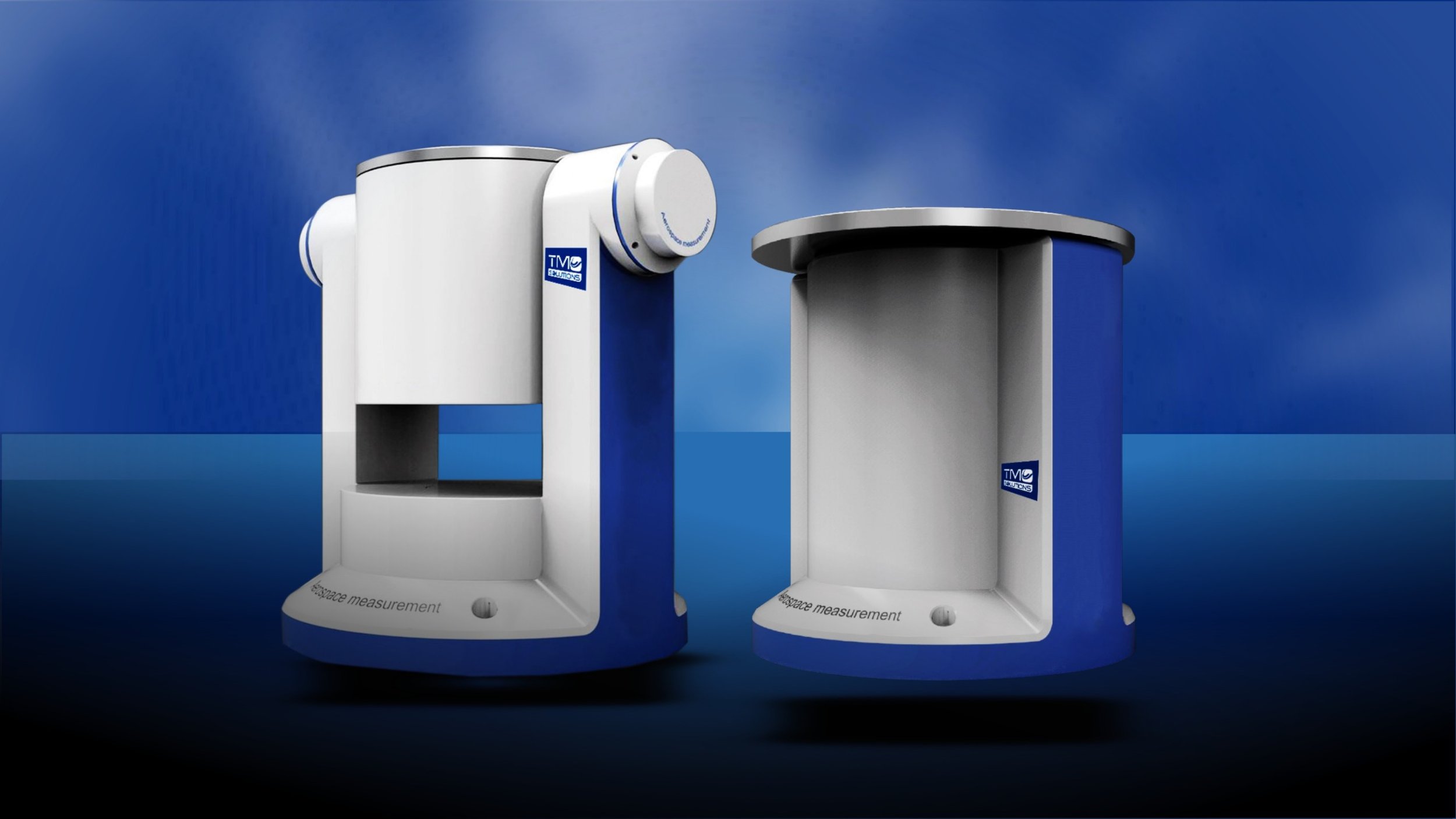

Boosting Precision with Motion Simulators & Rate Tables

In the fast-evolving industries of aerospace, automotive, and defense, ensuring product precision and reliability is a top priority. Motion simulators and rate tables have become indispensable tools in achieving this goal. By simulating real-world movements and testing rotational accuracy, manufacturers can refine their components to meet stringent quality standards and perform flawlessly in demanding environments.

Mastering Incline Impact Testing for Product Durability

In industries where products undergo frequent handling, transportation, and storage, ensuring durability and resilience is crucial. The incline impact testing system is an essential tool for manufacturers to assess how well their packaging and products can withstand impacts that may occur during their lifecycle.

Hydraulic vs. Electromagnetic Vibration Shakers

In the realm of vibration testing, choosing the right type of vibration shaker can be crucial for achieving accurate and reliable results. Two primary types of vibration shakers dominate the industry: hydraulic vibration shakers and electromagnetic (or electrodynamic) vibration shakers.

Optimizing Testing with Constant Acceleration Systems

In industries such as aerospace, automotive, electronics, and defense, ensuring product durability under various operational conditions is critical. One of the most important testing methods for validating product reliability and structural integrity is the centrifugal constant acceleration test.

Enhancing Packaging Safety with Drop Test Machines

In today's fast-paced global economy, products are often shipped across long distances and through various modes of transport. As a result, packaging plays a critical role in protecting products from damage during transit. However, even the most well-designed packaging can be subjected to sudden drops, impacts, and collisions, which could potentially compromise the integrity of the product inside.

Simulating Real-World Shocks for Product Reliability

In today’s competitive market, ensuring product reliability is critical for maintaining customer satisfaction and avoiding costly recalls. Whether you are in the aerospace, automotive, consumer electronics, or defense industry, products are often subjected to real-world shocks during shipping, installation, and operation.

Choosing the Right Shock Test System for Your Product

As industries like automotive, aerospace, consumer electronics, and defense continue to advance, the need for reliable products is more critical than ever. One of the most effective ways to ensure product durability and longevity is by conducting shock testing.