Exploring Features of the HSRS1000 SRS Machine

Understanding the Advanced Features of the HSRS1000 Shock Response Spectrum Machine

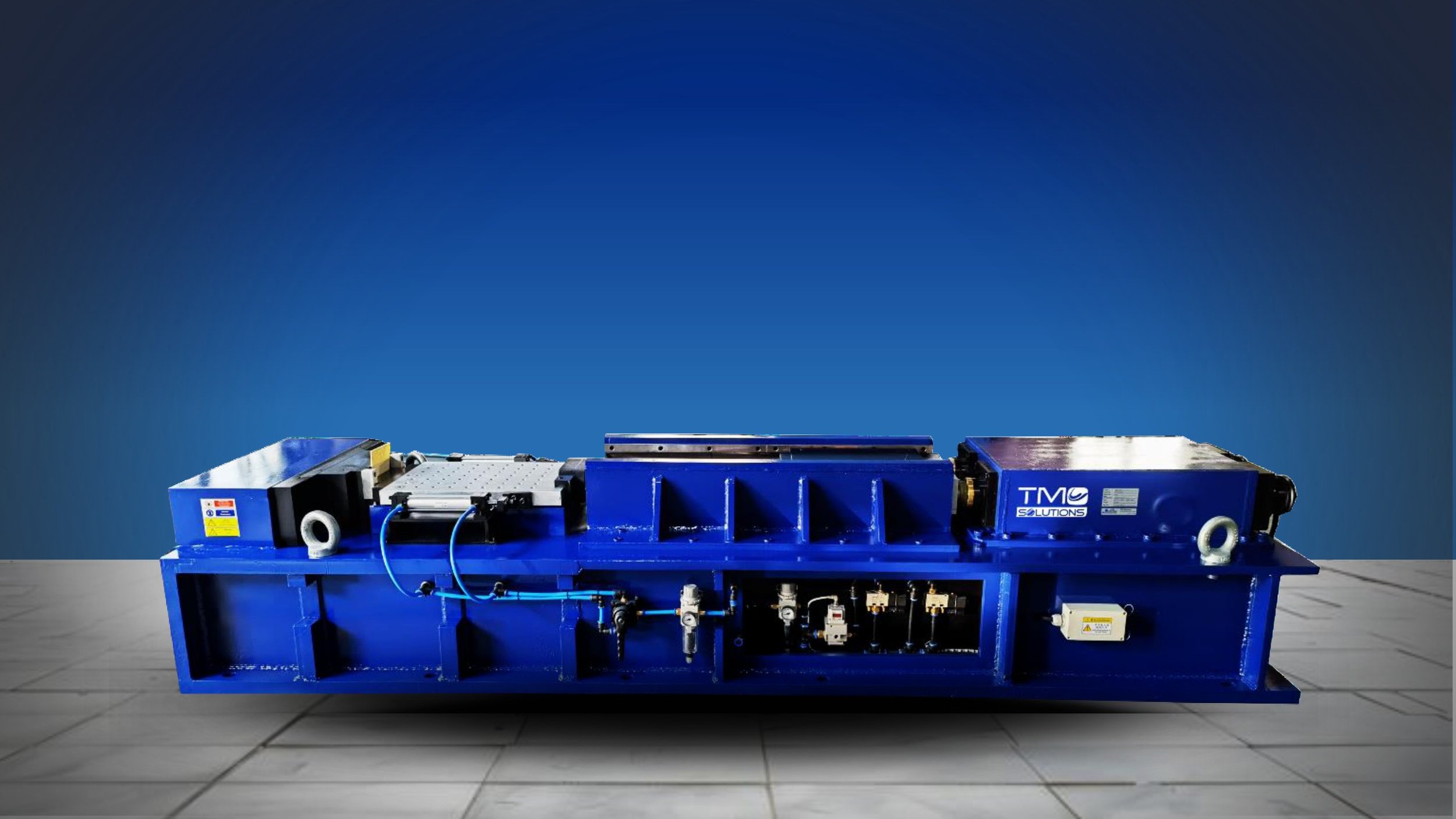

The HSRS1000 Horizontal Shock Response Spectrum (SRS) machine represents a leap in shock testing technology. Designed for industries such as aerospace, defense, and scientific research, this advanced system offers unmatched precision and flexibility in simulating shock events. This article dives into the features, benefits, and applications of the HSRS1000, offering insights into how it meets the rigorous demands of modern product testing.

The Need for Advanced Shock Testing

Shock testing evaluates how products withstand sudden impacts or accelerations. For industries like aerospace and defense, ensuring the reliability of components under extreme conditions is non-negotiable. SRS testing provides a detailed analysis of how products respond to varying shock frequencies and intensities, enabling manufacturers to identify potential vulnerabilities and improve product durability.

Key Features of the HSRS1000

Explosion-Proof, Energy-Saving Design

The HSRS1000 uses a pneumatic shock hammer, ensuring both safety and energy efficiency. Unlike traditional pendulum systems, its pneumatic design minimizes power consumption and reduces maintenance costs.

Superior Shock Energy

With a shock speed of up to 9m/s (compared to less than 6m/s in traditional systems), the HSRS1000 delivers 3-4 times the energy of older machines. This makes it ideal for high-energy applications.

Convenient Waveform Adjustments

The system simplifies waveform adjustments, reducing the risk of resonance plate damage and ensuring consistent performance.

High Repeatability

The HSRS1000 eliminates issues such as second shocks or clutch failures, ensuring precise and repeatable test results.

Applications of the HSRS1000

Aerospace and Defense:

Testing navigation systems, avionics, and other critical components.

Scientific Research:

Studying shock effects on experimental equipment.

Product Design and Development:

Ensuring components meet safety and reliability standards before market release.

Enhancing Safety and Efficiency

The HSRS1000 includes features such as noise reduction options, eye protection guidelines, and easy-to-maintain components. These measures not only ensure operator safety but also enhance the machine's operational efficiency.

Contact Us for More Information

Looking to elevate your shock testing capabilities? Contact TMC Solutions today to learn more about the HSRS1000 and how it can enhance your product testing processes.