HAS Series High-Energy Horizontal Shock Tester: Comprehensive Overview

Introduction and Working Principle

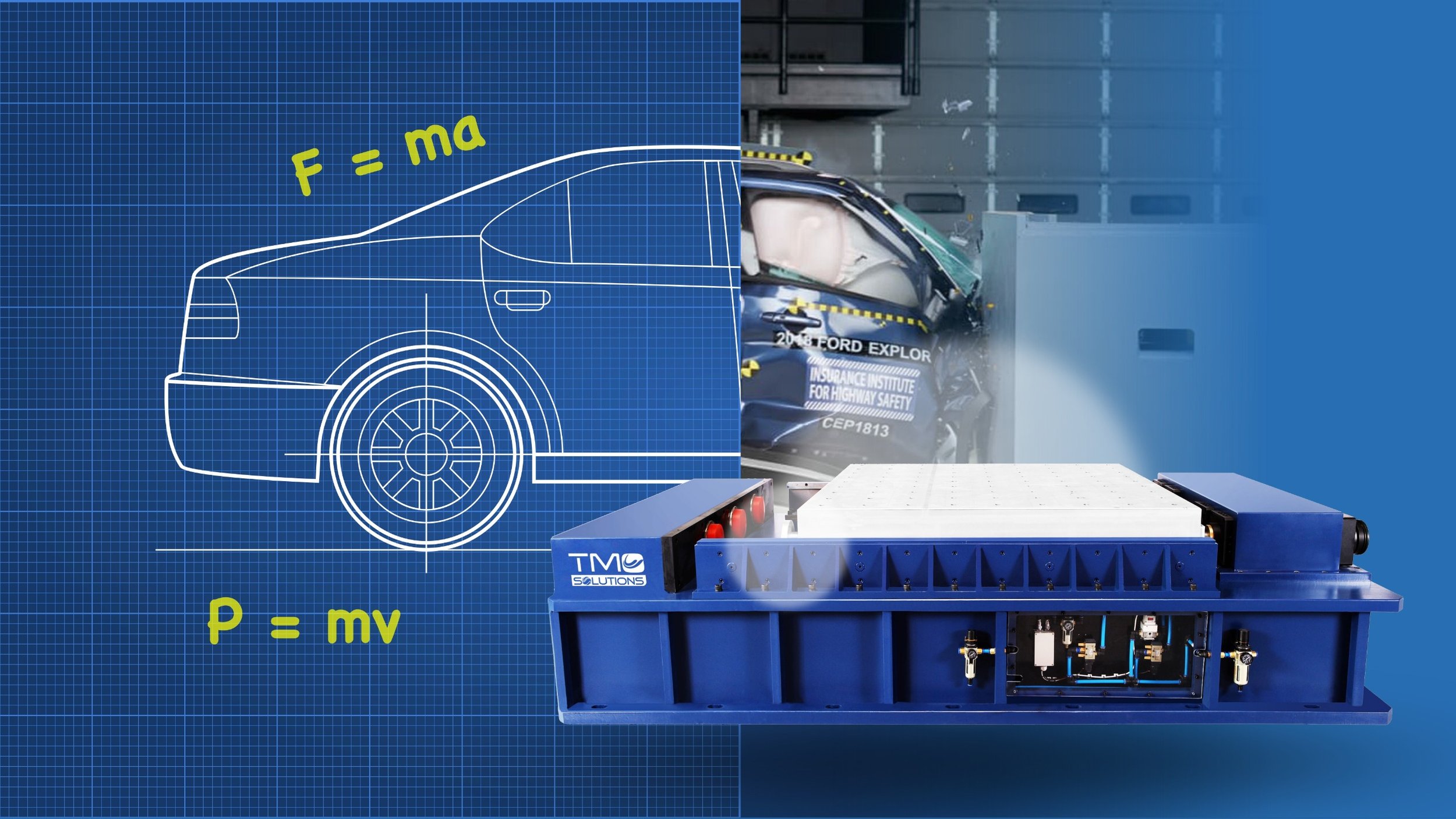

The HAS Series High-Energy Horizontal Shock Tester is a state-of-the-art piece of equipment designed to conduct comprehensive horizontal shock and simulated collision tests. This advanced tester simulates the shock damage that products might encounter during real-world use, providing critical data to evaluate the shock resistance of product structures and assess their functional reliability and structural integrity in actual shock environments. The insights gained from these tests help designers and manufacturers enhance or optimize the structural strength of their products.

Horizontal Shock Testing

Horizontal shock testing is used to simulate the impact damage a product may experience during actual use. The data collected from these tests helps in evaluating the product's shock resistance, ensuring it can withstand real-world conditions. This testing is essential for validating the durability and reliability of the product’s structure and functionality, leading to better product design and performance.

Simulated Crash Testing

Simulated crash tests are primarily used to verify the safety performance of rechargeable energy storage systems, including battery modules or packs, under inertial loads during vehicle collisions. The test objects are mounted horizontally on a table with a bracket, and specific pulses are applied to the shock table according to the test object's use environment. The driving direction of the car is aligned with the x-axis, while the other horizontal direction, perpendicular to the driving direction, is the y-axis. These tests are crucial for ensuring the safety and reliability of energy storage systems in vehicles.

Main Performance Advantages

High Reliability and Safety: Driven by low-pressure compressed air, the HAS Series offers high reliability and safety, excellent shock repeatability, simple operation, convenient maintenance, and eco-friendly features with no pollution.

Compact Design: Utilizing multi-cylinder synchronous drive technology, it produces very high shock speeds over a short distance while occupying a small area.

Versatile Testing Capabilities: Capable of performing high-energy horizontal shock tests and simulated collision tests with large pulse widths exceeding 80ms, with convenient waveform adjustments and straightforward operation.

Enhanced Durability: Multiple waveform generators used in parallel are easy to install and significantly improve the waveform generator's service life.

Anti-Secondary Shock Device: Equipped with an anti-secondary shock braking device to effectively prevent secondary shocks.

Advanced Data Communication: Based on the Windows operating system, it achieves high-speed data communication with the shock control measuring instrument via computer network ports, USB interfaces, or serial ports, allowing comprehensive system test settings, command operations, signal and data display, and storage.

User-Friendly Software: The supporting shock control measurement software simplifies parameter settings and generates corresponding test reports after completion.

Robust Construction: The shock table is made from high-strength aircraft aluminum, offering high strength and hardness properties and excellent frequency response characteristics.

Efficient Energy Conversion: Featuring a large mass counterweight base, it minimizes the loss of potential energy converted into mechanical energy during shocks, enhancing overall efficiency.

Technological Advancements: Incorporates advanced devices such as pilot-operated high-frequency high-speed cylinders, new control valves, rapid intake and exhaust systems, and synchronized intake and exhaust systems with independent intellectual property rights, placing the shock system at the forefront of technological advancement, functionality, and reliability.

Customizable Options: Products can be customized and optimized based on user requirements, including table size, load weight, shock acceleration, and pulse width, to meet various specific needs.

Equipment Main Specifications

The HAS Series High-Energy Horizontal Shock Tester offers an impressive range of specifications to accommodate various testing needs. These include adjustable parameters such as shock acceleration, pulse width, load capacity, and more, ensuring that the equipment can be tailored to meet the unique requirements of different industries and applications.

For more information on the HAS Series High-Energy Horizontal Shock Tester or to discuss your specific testing needs, contact TMC Solutions today. Our team of experts is ready to help you enhance the reliability and performance of your products with cutting-edge testing solutions.