Advancing Defense Testing with TMC Shock Systems

In defense applications, the stakes are incredibly high. Every component, system, or piece of equipment must perform flawlessly under extreme conditions. From shockwaves generated by rocket launches to the sudden impacts caused by artillery firing, the environments faced by defense products demand rigorous testing.

Simulating Real-World Shocks for Product Reliability

In today’s competitive market, ensuring product reliability is critical for maintaining customer satisfaction and avoiding costly recalls. Whether you are in the aerospace, automotive, consumer electronics, or defense industry, products are often subjected to real-world shocks during shipping, installation, and operation.

Choosing the Right Shock Test System for Your Product

As industries like automotive, aerospace, consumer electronics, and defense continue to advance, the need for reliable products is more critical than ever. One of the most effective ways to ensure product durability and longevity is by conducting shock testing.

Reliability Testing in Aerospace & Automotive

In high-stakes industries like aerospace and automotive, ensuring the reliability of components and systems is not just essential—it’s critical for safety, performance, and longevity. Both sectors operate under conditions that challenge every part of the vehicle or aircraft, from the engines and electronics to materials and structures.

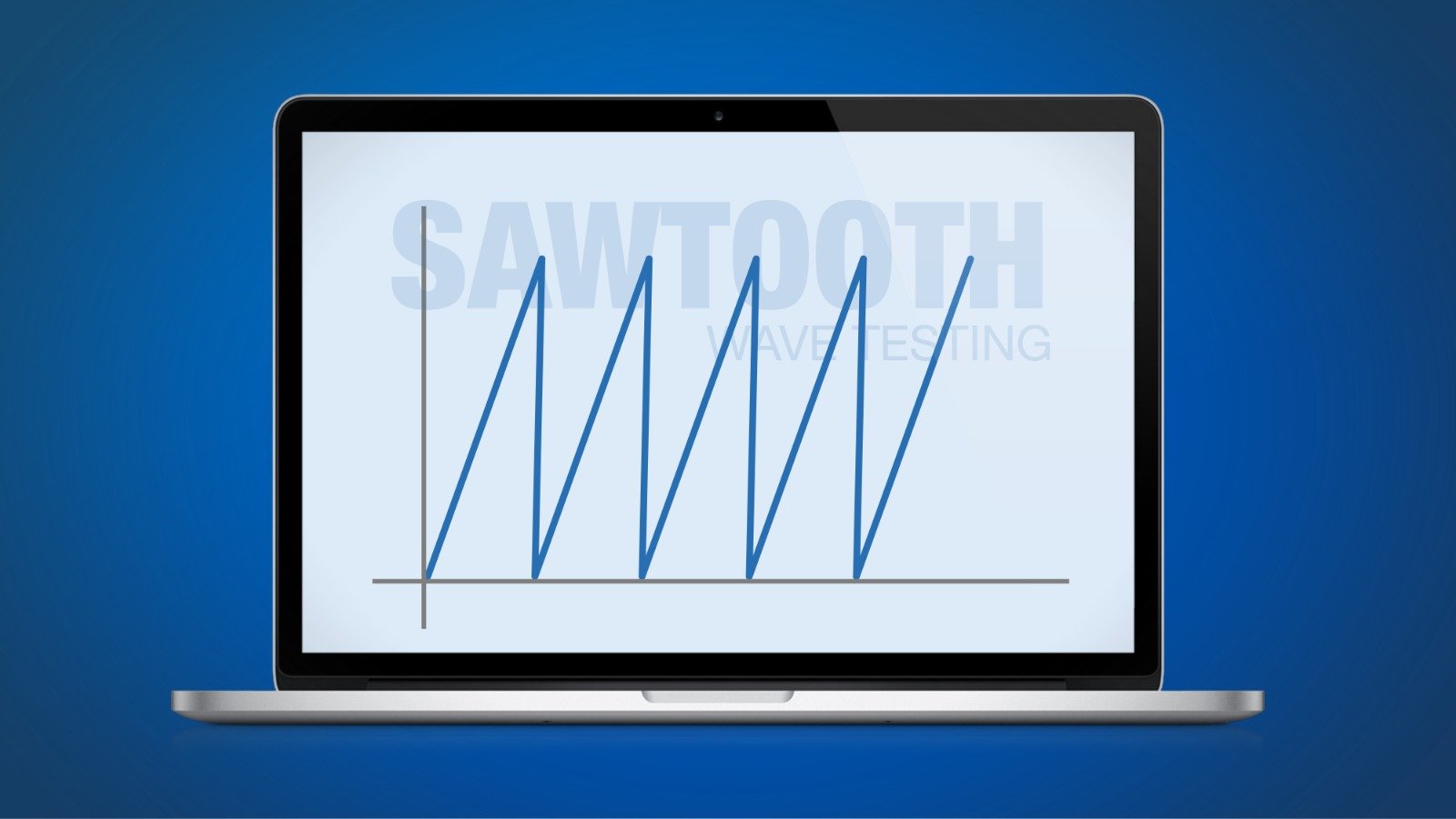

Sawtooth Wave Testing for Product Durability

In the field of mechanical testing, ensuring that a product can withstand the harsh conditions it may face during its lifecycle is crucial. One critical test for this is shock testing, which simulates the physical shocks that a product might experience during transportation, handling, or use.

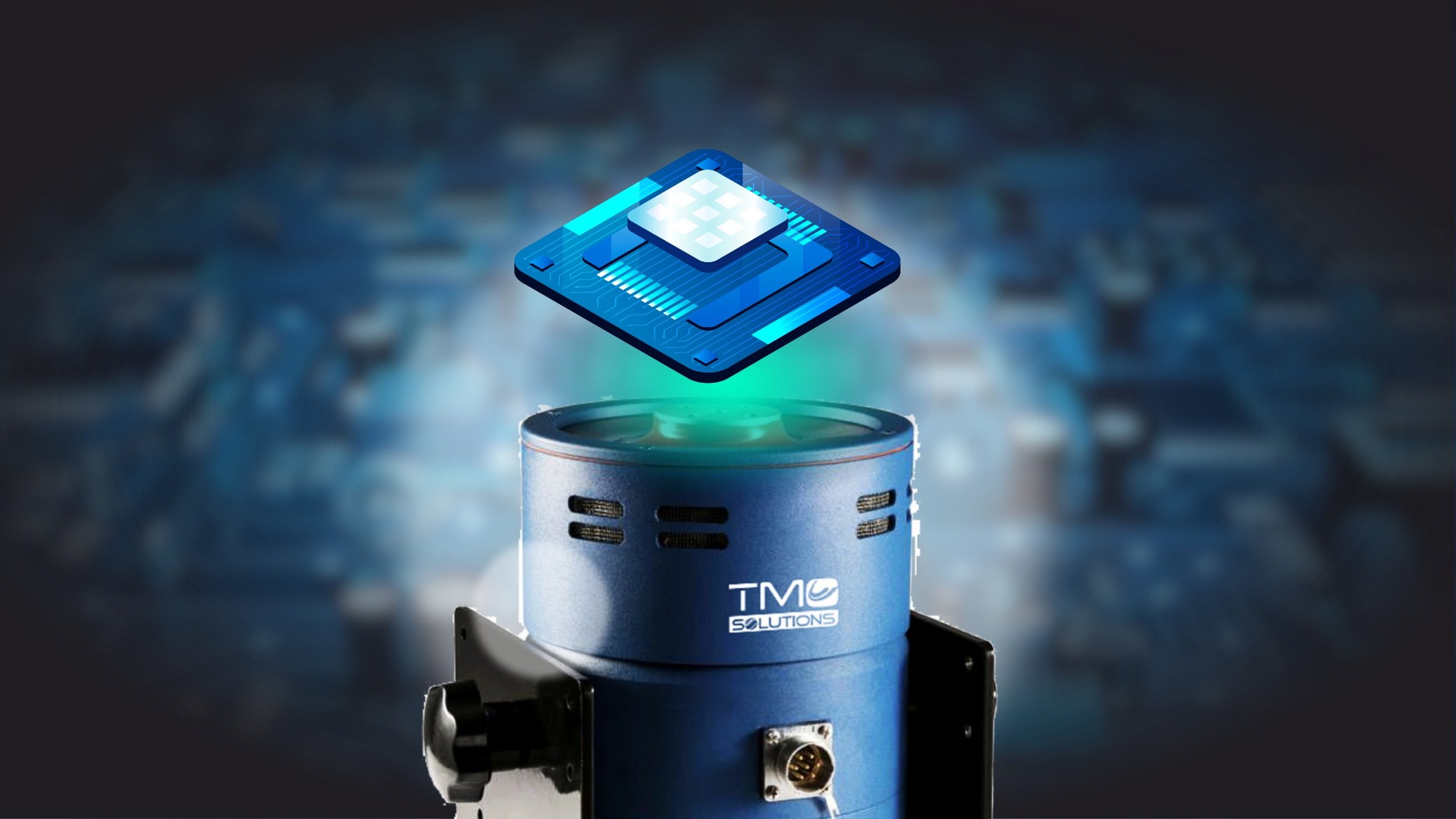

VT Series: Compact Shaker for Precision Vibration Testing

TMC Solutions' VT Series Small Vibration Test System is engineered specifically to meet the needs of modern manufacturers seeking a compact, efficient, and reliable solution for vibration testing of smaller components and products.

Enhancing Safety with Hydraulic Vertical Shock Test Systems

In industries such as electronics, automotive, and aerospace, ensuring product durability during manufacturing, transportation, and real-world use is paramount. A critical part of this process is shock testing, where products are subjected to controlled impacts to assess their structural integrity and performance.

Ensuring Product Reliability with Shock and SRS Tests

In the dynamic and ever-evolving world of electronic and mechanical products, ensuring reliability under extreme conditions is crucial. One of the most effective ways to achieve this is through shock testing and analyzing the Shock Response Spectrum (SRS).

Ensuring Reliability and Longevity of EV Batteries

The rapid adoption of electric vehicles (EVs) is a critical component of the global transition to sustainable transportation. As EV technology continues to evolve, the reliability and longevity of EV batteries remain paramount.

The Benefits of Partnering with a Reliable Testing Solutions Provider

In today’s highly competitive and technologically advanced market, the need for reliable testing solutions has never been more critical. Whether you are in aerospace, automotive, electronics, or any other industry, ensuring the durability and reliability of your products is paramount. Partnering with a reliable testing solutions provider can make all the difference in achieving these goals.

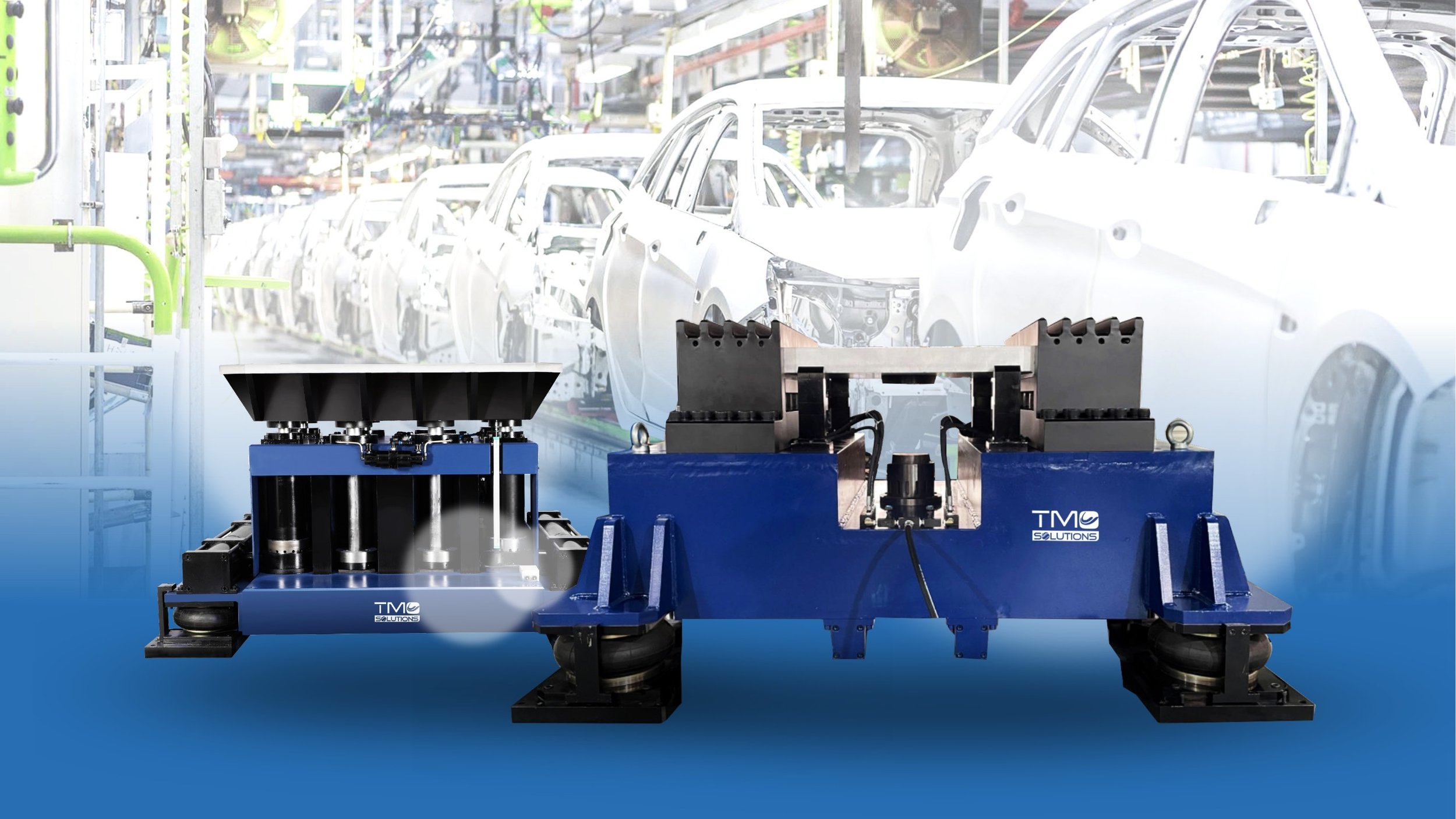

HAS Series High-Energy Horizontal Shock Tester: Comprehensive Overview

The HAS Series High-Energy Horizontal Shock Tester is a state-of-the-art piece of equipment designed to conduct comprehensive horizontal shock and simulated collision tests. This advanced tester simulates the shock damage that products might encounter during real-world use, providing critical data to evaluate the shock resistance of product structures and assess their functional reliability and structural integrity in actual shock environments.

The Importance of Customized Shock Testing Solutions for Unique Industry Needs

In today's highly competitive industrial landscape, the importance of ensuring product reliability and durability cannot be overstated. Industries such as aerospace, automotive, electronics, and defense demand rigorous testing to guarantee that their components can withstand real-world conditions.

Advanced Techniques in Environmental Stress Screening for Electronics

In the fast-evolving world of electronics, ensuring the reliability and durability of components is crucial. Environmental Stress Screening (ESS) is a pivotal process in identifying potential failures before products reach the market.

The Role of Shock Testing in Ensuring Aerospace Component Integrity

In the aerospace industry, where safety and precision are paramount, shock testing plays a critical role in ensuring the integrity and operational readiness of components. This process simulates the sudden and extreme forces that aerospace components might encounter during their lifecycle, such as impacts during launch, flight, and landing operations.

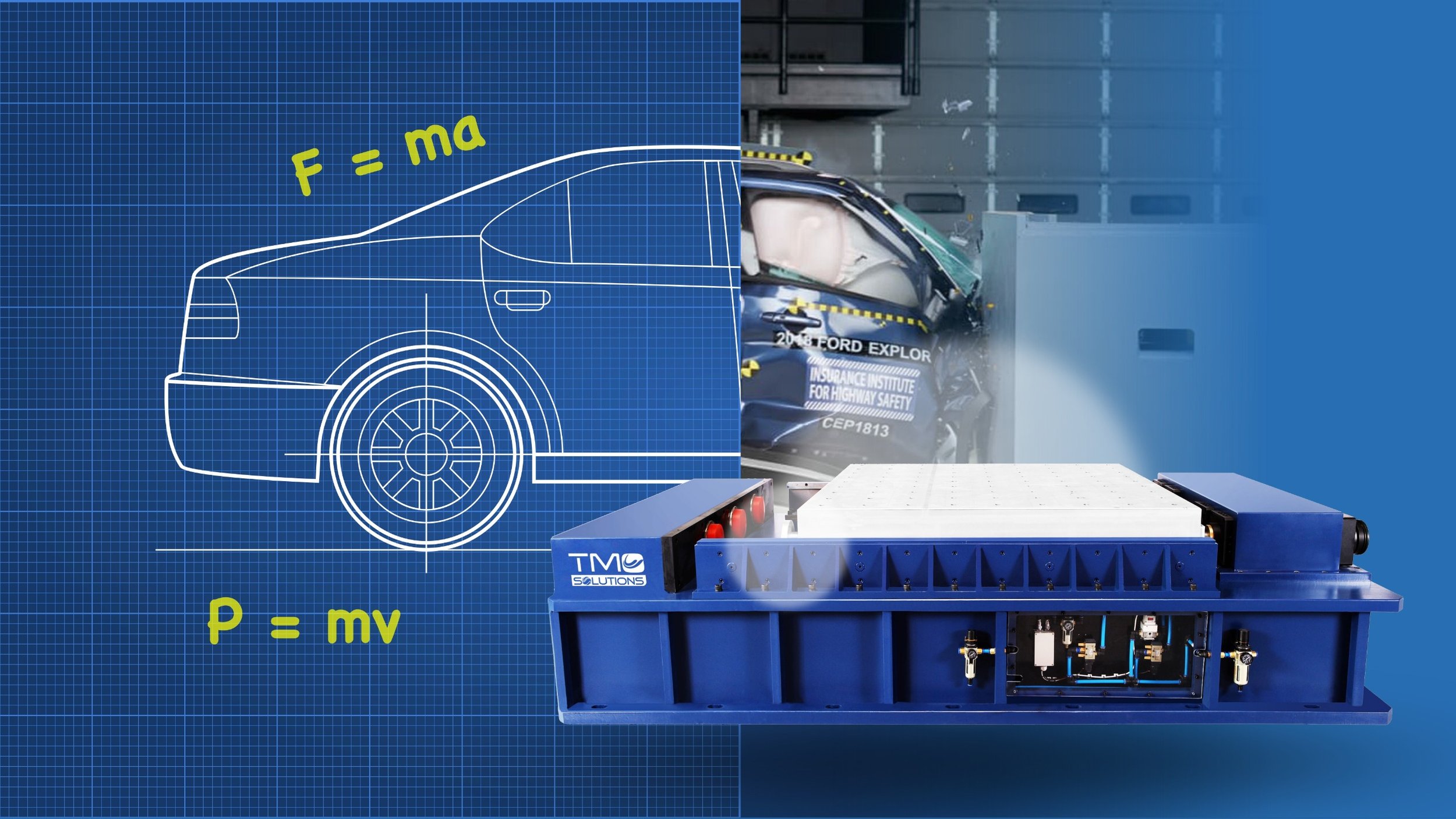

How Reliability Testing Enhances Product Durability in the Automotive Industry

In the competitive automotive industry, the durability and reliability of a vehicle are paramount for maintaining customer trust and brand reputation. Reliability testing plays a critical role in ensuring that every component of a vehicle can withstand the rigors of daily use and adverse conditions.

The Essentials of Reliability Testing in Product Development

Reliability testing is a fundamental aspect of product development, crucial for preserving brand reputation and building consumer trust in sectors such as aerospace, automotive, and electronics and many others.