Centrifuge Testing: Key Parameters & Optimization Tips

When conducting centrifuge testing, several essential parameters must be considered to ensure accurate and effective separation or analysis. These parameters depend on the specific application, but the most common ones include

Optimizing Testing with Constant Acceleration Systems

In industries such as aerospace, automotive, electronics, and defense, ensuring product durability under various operational conditions is critical. One of the most important testing methods for validating product reliability and structural integrity is the centrifugal constant acceleration test.

Guide to Selecting Your Ideal Centrifuge System

When it comes to ensuring the reliability and performance of electrical and electronic products, constant acceleration testing is a critical process. According to national standards, the purpose of constant acceleration tests is to determine whether the structural adaptability and performance of components, equipment, and other electronic products can withstand forces generated by a steady-state acceleration environment.

Exploring the Versatile Box-Type Centrifuge Tester

The box type centrifuge is a standout in laboratory equipment, known for its versatility and capability, making it essential for various scientific and industrial applications.

The Importance of Testing Electronic Parts of Aerospace Devices with Constant Acceleration Test Machines

In the high-stakes world of aerospace, the reliability and integrity of electronic components are non-negotiable. Every part, no matter how small, must perform flawlessly under extreme conditions to ensure the safety and success of missions.

The Benefits of Partnering with a Reliable Testing Solutions Provider

In today’s highly competitive and technologically advanced market, the need for reliable testing solutions has never been more critical. Whether you are in aerospace, automotive, electronics, or any other industry, ensuring the durability and reliability of your products is paramount. Partnering with a reliable testing solutions provider can make all the difference in achieving these goals.

The Importance of Customized Shock Testing Solutions for Unique Industry Needs

In today's highly competitive industrial landscape, the importance of ensuring product reliability and durability cannot be overstated. Industries such as aerospace, automotive, electronics, and defense demand rigorous testing to guarantee that their components can withstand real-world conditions.

Advanced Techniques in Environmental Stress Screening for Electronics

In the fast-evolving world of electronics, ensuring the reliability and durability of components is crucial. Environmental Stress Screening (ESS) is a pivotal process in identifying potential failures before products reach the market.

The Role of Shock Testing in Ensuring Aerospace Component Integrity

In the aerospace industry, where safety and precision are paramount, shock testing plays a critical role in ensuring the integrity and operational readiness of components. This process simulates the sudden and extreme forces that aerospace components might encounter during their lifecycle, such as impacts during launch, flight, and landing operations.

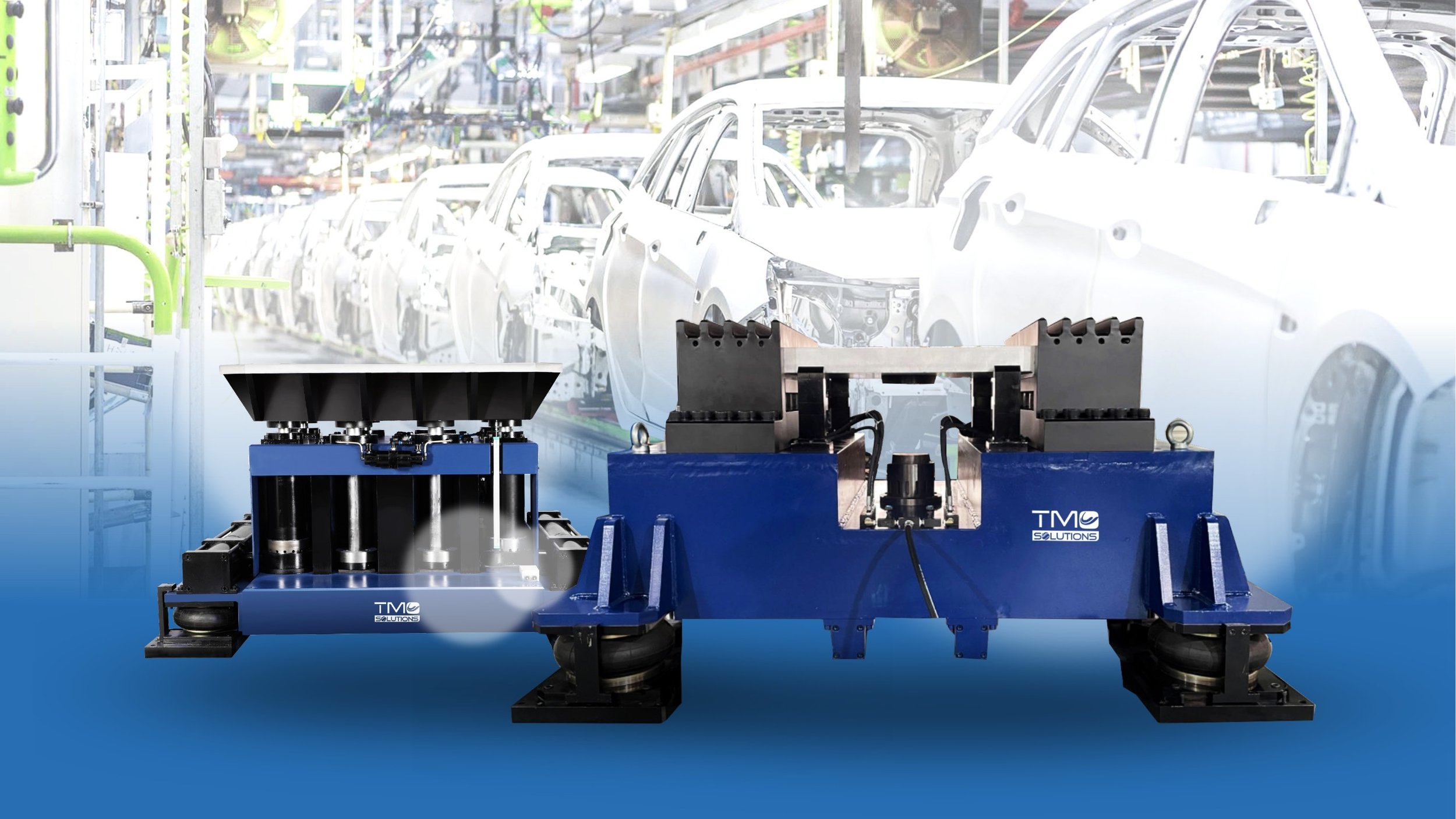

How Reliability Testing Enhances Product Durability in the Automotive Industry

In the competitive automotive industry, the durability and reliability of a vehicle are paramount for maintaining customer trust and brand reputation. Reliability testing plays a critical role in ensuring that every component of a vehicle can withstand the rigors of daily use and adverse conditions.

The Essentials of Reliability Testing in Product Development

Reliability testing is a fundamental aspect of product development, crucial for preserving brand reputation and building consumer trust in sectors such as aerospace, automotive, and electronics and many others.